Categories

- PID Controllers

- Auto gauges, EGT Boost

- Coffee Machine Kits

- Brew Equipment

- Power Regulators

- Powder Coating Equipment

- Powder Coating Ovens

- Smoker Controllers

- Humidity Controllers

- Plug-n-Play Controllers

- Thermometer, Process Meter

- Temperature Sensors

- SSRs & Contactors

- Timer, Counter, Tachometer

- Pressure Controller

- Controller for Coil Heater Enail

- Enclosures (Boxes)

- Switches

- Punch & Die for Control Panel

- DIN Rail Components

- Connectors

- Accessories

- Control Panels & DIY Kits

- Sous Vide Cooking

- Liquid Dispensing Machine

- Controller For Lab Research

- Silicone Tubing (Platinum Cured)

- Value Packs

- Scratch/Dent/Refurbished

- Services

- Specials ...

- Featured Products ...

- All Products ...

Recommendation for kiln control / heat treatment ovens

A. Recommended part list:

1) A programmable controller with ramp/soak function and SSR output.

Popular choice: SYL-2352P

Ramp soak with USB/computer access: SYL-5352PA

Ramp soak with WiFi/App: AW-SYL-2352P

Ramp soak with LCD and Bluetooth: N20K48

2) A solid state relay (SSR). The SSR needs to be able to handle the current of your heater. Most buyers use either a 25 A SSR or a 40 A SSR. For some larger oven or kiln with multiple heating elements, multiple SSRs are used by paralleling the inputs of the SSR together. Our SSR are listed at

25A SSR

40A SSR

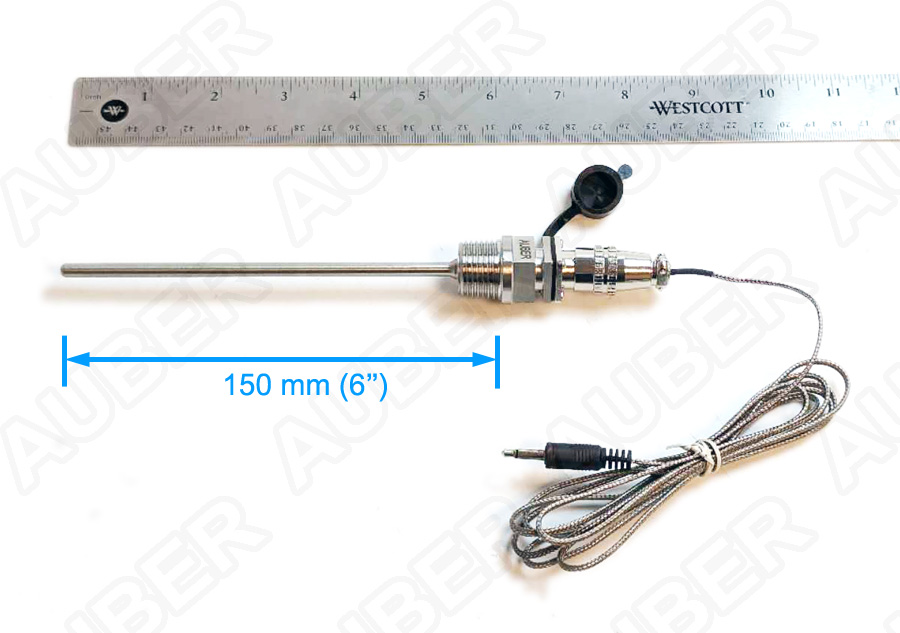

3) A high temperature probe. We have one sealed high temperature probe can work a maximum of 2000F. It is good for glass kiln. It is listed at

WRNK-191

For some ceramic kiln, 2000F might not be high enough. Here is the sensor for it

TC-K-KLN

4) Heat Sink.

Heatsink for 25A SSR

Heatsink for 40A SSR

5) A project box, switch, and fuse that can be found from you local Radio Shark store.

Also, you can click HERE for the details about how to upgrade kiln with PID controllers.

Please note:

For Kiln that draws more than 25 A, many people prefer to use an electromechanical switching devices, such as a contactor or a mercury switch, instead of SSR. This is because removing the heat generated from SSR becomes an important issue for high current SSR. If the SSR gets over heat, it will fail. When an electromechanical switch fails, it normally ends up open circuit. The heating will stop. But when the SSR fails, it normally ends up short circuit. The heating will continue without stop. That can lead to a mess. That is the disadvantage of SSR. The advantage of SSR is infinite life time (if used properly) and precise temperature control (because it can be switched at high speed). If you want to use electromechanical relay instead of SSR, or your kiln has a contactor switch and you want use it instead of a SSR, you can eliminate item “2)” and change the controller to SYL-2342P.

If your kiln already has a thermocouple that is in good condition, you can eliminate item “3)”.

Typical wiring diagram (SYL-2352P):

B. Kiln application note for SYL-2352P. Credit: @h.bomb.hanno_21